Introduction

This post is based on a presentation I gave to all of the staff of Pete Fowler Construction.

I began: “You’re going to have to be patient with me for the next 20 minutes or so. I want to have a long, slow conversation about “Quality.” If you don’t know this already, I have been thinking a lot about this, for a long time. It is my guess, that based on how I sometimes act, that you’ll be surprised by what I think about ‘Quality.’ Now let’s listen to a great song, performed by great artists.”

Examples of Quality

The Zutons - Valerie

I love this song.

I did not realize that the Amy Winehouse version I first heard back in the mid-2000’s was a 1-year old cover from a rock band when Winehouse covered it.

Big budget production

Big budget video

Mark Ronson featuring Amy Winehouse - Valerie

It’s better to skip the first one minute.

Awesome Cover Song

High quality

High budget production

High budget video

The “Artist” is not even in the video. So the “Performers” are not the artist.

It’s got a totally different feel than the original

MUCH more soul music feel

Teddy Swims - Valerie

Note that the title of the YouTube video even says “Amy Winehouse Cover”

Boom!

High quality

Low budget recording

Low budget video

Simple

It’s SO different!!

Bonus Songs (Listen Later)

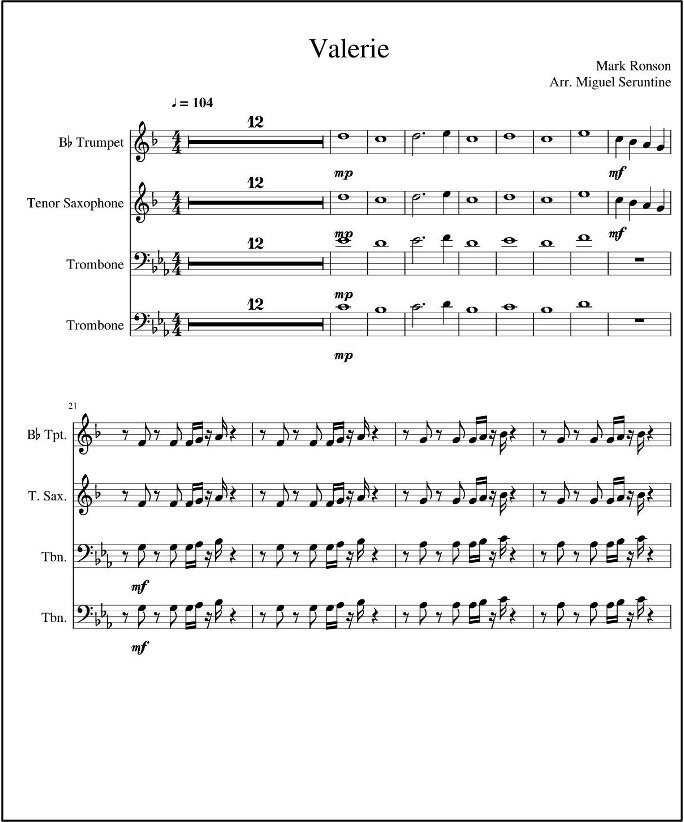

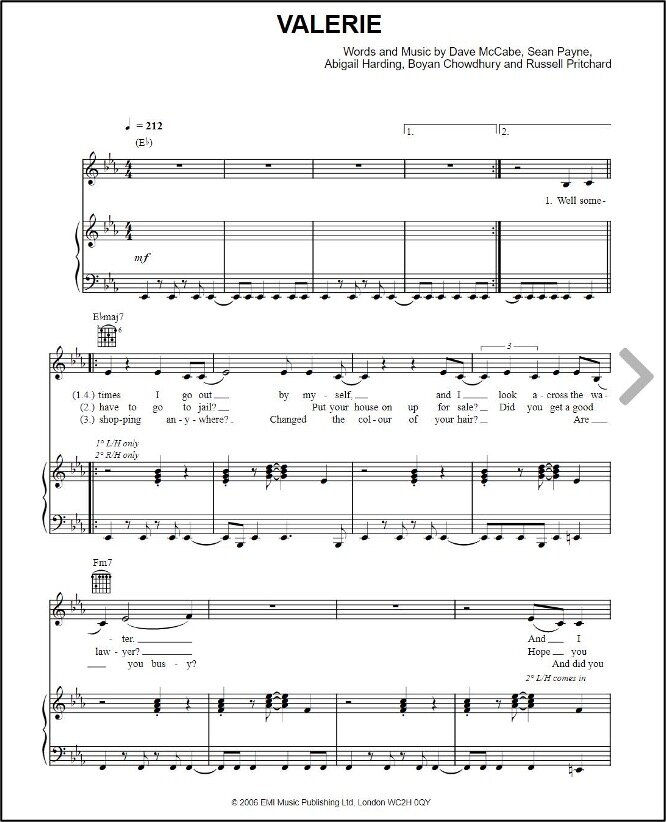

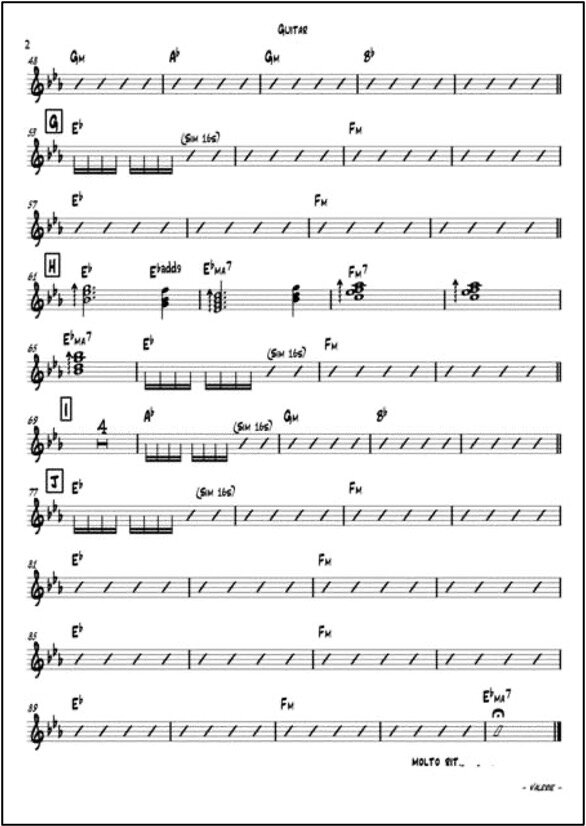

Sheet Music for Valerie

See the spectrum of specificity in the sheet music available for Valery

VERY explicit

Less explicit

Less explicit

Less explicit

Very NOT explicit (This is the only one I understand).

SIMILARITIES: Obviously the same song. Same chord progression. Same words. All awesome work.

DIFFERENCES: Key. Tempo. Level of specificity.

Who We Are & What We Do

Our Clients & Process

Our Experts and Project Managers

Should these people be playing the exact notes and dance steps every time?

What We Have Learned About Quality

Steve Jobs on Quality

This is deeply fascinating to me and demonstrates very clearly and obviously how Steve Jobs was able to create, in his own lifetime, the most valuable and esteemed company in the world. The first 11 minutes and 10 seconds are key. I have now watched this more than 10 times. He was only 35 years old. The depth of knowledge and wisdom is humbling to me.

My key take-aways include:

Most of what we do in business are repetitive processes.

Repetitive processes can be examined “scientifically,” taken apart, reengineered, and put back together in a way that makes them more efficient and effective.

Those who plan and improve best are likely to be the winners.

Optimistic humanism is a wonderful thing.

Quality and process improvement is a loop that begins and ends with the customer.

“Because that’s the way we do it here” is a terrible answer to almost any question in a human organization. There should be a reason things are done the way they are and there should be opportunities to question the reasons.

The people who work in companies are smart. And if given the opportunity to improve their processes, they will.

People should not have to ask permission to improve work processes. They should be empowered with tools to analyze, measure, and improve their own processes, without asking for permission.

Quality and Continual Improvement

The Definition of Quality

Quality is what we started this presentation with… When you watch those music videos and listen to those artists play those songs, you know they are of “high quality.” Even if you don’t like them. We know it when we see it.

I spent a long time and a couple thousand words trying to nail The "Definition of Quality". I mostly failed. It defies a broadly applicable definition. Even Miriam-Webster’s took 14 tries… literally. In our company, when we “grade” work on a 5 or 10 point scale, we ALWAYS come within one or two points of each other’s score. Always. Quality is hard to define, but easy to judge.

For our company, judging whether work is “high quality” or not is similarly easy, and also similarly difficult to define. If it’s incorrect, or even just unclear, then it is low quality. We “deliver” work to clients in many ways: verbally over the telephone, verbally and graphically via a web meetings like Zoom or Google Meet, verbally and graphically in person, in written reports and cost estimates, in formal presentations, and via sworn testimony. When they receive it, if they think “Those people are smart,” and “Those people have their act together,” and “My project is safe in their hands,” then it’s high quality. In addition, the work needs to conform with our Core Values, where we Act with Integrity; Solve the Problem; and Do Awesome Work where we (1.) always communicate in plain English that everyone can understand; (2.) turn data into information so we, and our clients, can use it to make smart, informed decisions; (3.) to prescribe a set of SMART (specific, measurable, assertive, realistic and timed) recommendations or opinions that (4.) will move our client from where they are to the best available alternative as quickly and inexpensively as possible. And since we are a company, and consistency is known to breed comfort, the “look & feel” of the work each of us delivers should be remarkably similar to the work delivered by others from our organization.

Kaizen = Continual Improvement

Kaizen is a Japanese term meaning "change for the better" or "continual improvement." It is a Japanese business philosophy to continually improve operations by involving all employees. The philosophy is about creating a company culture where everyone is focused, virtually every day, on making small but measurable improvements that remove waste, making the organization dramatically more effective over time. The ultimate aim is perfection with zero waste, but with the peaceful understanding that humans can never achieve perfection, so the opportunities for improvements can be identified and executed forever.

After World War II Japan’s country and economy was devastated. Beginning in the late 1940s and early 50s some of the best American industrial engineers were sent to help them rebuild their industries. The fundamentals of Scientific Management resonated with the Japanese culture of respect and precision. In the U.S. at the time, many businesses were (and many remain) locked in a “Management versus Labor” war that was the opposite of the respect and trust the Japanese had. The Japanese trust and respect allowed them to radically humanize the tools of scientific management by teaching them, not only to managers, but to everyone in the company, including line-level workers. So everyone became responsible to continually improve all of their own processes, forever. This humanization of scientific management was a world-changing revolution, like the invention of the wheel, agriculture, metal tools and weapons, guns, telephones, airplanes, computers, etc. The societies and companies who mastered this new technology were going to rise, and those who could not, would suffer decline. By the early 1970s, the Japanese were displacing U.S. manufacturers in every area where they competed. By the end of the 1970s the U.S. auto manufacturers were almost put out of business and required a government bailout because the Japanese cars were so much less expensive and more reliable (See the book The Machine That Changed the World).

The Japanese companies figured out how to overcome the natural human tendency toward tribalism. I’ve always been dumbfounded when I’ve seen an “us versus them“ attitude between offices or departments of the same company. It’s happened to us on many occasions. It’s kept us from becoming the best we can be. People in the same organization need to be inspired to work together, all rowing in the same direction, with the same goals, objectives, and strategizing for improving the whole. When we see “us verses them” we need to fight the urge to get mad. We need to remember that it’s natural, and that cooperation “outside our immediate tribe” is not natural for humans. We need to deal with the situation with tremendous lovingkindness (I know that sounds weird in business, but it’s true). We need to take a deep breath and figure out how to make the person or group who are feeling “us verses them” feel safe enough to open up and participate in Kaizen.

Kaizen’s objective (goal) is almost always to eliminate waste by doing things right the first time; most importantly by eliminating rework or causing problems downstream. Like all things in “Lean” organizations the Kaizen Project (sometimes called a “Kaizen Event”) should be made as simple as possible, so as to eliminate errors (waste).

In short, the principles of Kaizen include (1.) Good processes create good results. (2.) Improvements are made by the people doing the work. (3.) Improvements are based on small changes. And (4.) Improvements must be measurable, standardized, and repeatable.

Standard Work

Good processes must be memorialized (written, graphic, video, etc.), available “at the Gemba” (where the work is performed), and should be in some standard form the personnel decide on, company wide. These documented, explicit, step-by-step, rubber-on-road processes are called “Standard Work” (or sometimes Standardized Work). The format of this can be unique for every organization, but it is simply the written and graphic description of exactly how a process is performed and quality-checked.

Opportunities for improvement are often identified when someone recognizes a “defect” that will require rework, and brings this to the attention of a manager. Sometimes the Kaizen Project can be executed immediately, solving the problem permanently throughout the organization by updating the “Standard Work” documentation and sharing it with everyone who needs to know. But sometimes a more scientific (like measuring and counting things) and project management style approach needs to be applied.

Kaizen Projects (Kaizen Events)

A Kaizen Project, sometimes called a Kaizen Event, is a process improvement project where the objective is measurable improvement, memorialized in Standard Work documentation that typically includes process maps, step-by-step instructions, quality verification mechanisms, and training. A Kaizen Project can be large or small; but small is better.

We teach everyone in the company to…

Identify bottlenecks or pain-points.

Begin to “Stabilize” the process by executing a “Kaizen Project” including

“Going to the Gemba,” which means going to where the work is done and engaging the people doing the work.

Define the current process, which often includes creating a “Process Map” and written and other graphic, step-by-step “Standard Work” documentation that everyone can agree upon.

Measure productivity, quality, and variation and chart it graphically.

Analyze and conduct experiments trying to improve productivity, quality, and consistency, and chart it graphically.

Update the Standard Work documentation with the improvements, and make sure they are stored in a place that everyone knows is the “Single Source of Truth” and are always available to reference when and where the work is being performed;

Include in the Standard Work documentation how conformance with the standard will be verified or “controlled” before sending the work downstream to the next process or to the client; this often includes how we will make 100% sure that 100% of the people working the process are trained to mastery, quality assurance inspection, peer review, quality control, etc.

The people who use the improved process are trained and empowered to repeat this Kaizen Project process to “Continually Improve,” forever, using more and more sophisticated “Quality Improvement Tools” (see a list of some of them, below).

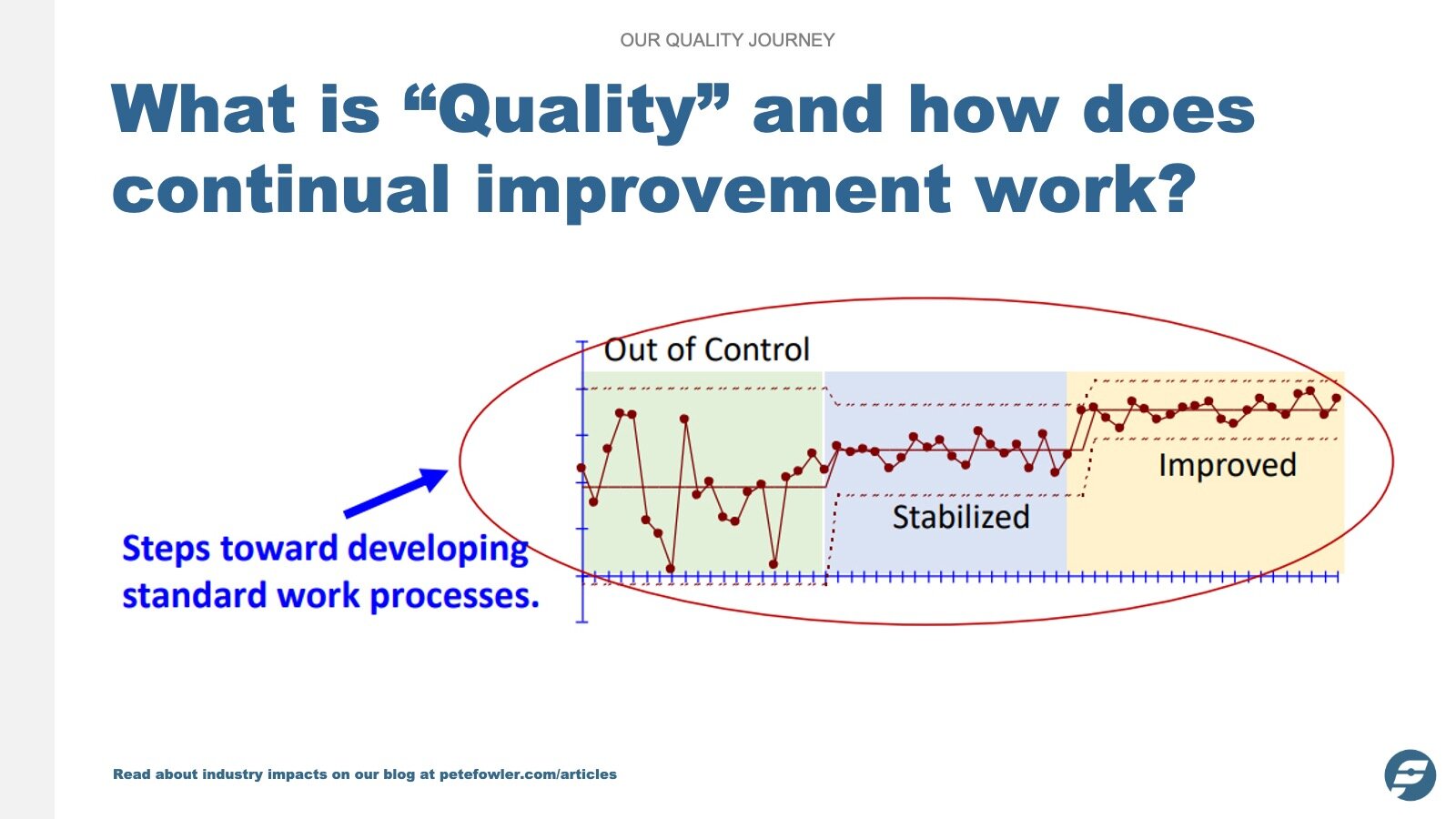

Stabilized Processes

One of the most difficult parts of this process is getting the Standard Work or Best Practices “Stabilized.” See the “What is quality and how does continual improvement work?” graphic above. With Stabilized Processes we have predictable measures, within a statistical range of variation, like: minutes or hours/unit of production; defects/inspection; % closed sales/sales meeting; new projects/month; customer satisfaction/closed project; quality score/audit; billable hours/consultant; errors/document; completed checklists/month; pages/hour; and on and on.

Without Standard Work the variability in process and output from person to person is dramatic, and out of control. A process becomes “Stabilized” when it is defined (written and graphic), agreed upon, available when and where the work is performed, used by 100% of the people 100% of the time, and performance is measured by the built-in quality verification mechanisms, before the work moves downstream, so that “Rework” is virtually eliminated. This is really hard and many companies never develop the culture required to successfully pass through this “Valley of Death” between Organizational Maturity levels 2 and 3, that I wrote about in 2019. Processes need to be Stabilized before they can be improved. Organizations with Stabilized Processes run with very little drama, perform well on virtually all measures, especially customer satisfaction, and the people who work in the organization have enthusiasm and pride.

Deep Thoughts on Continual Improvement

This all seems so simple. Why do so few companies do it? It’s really hard at first. Humans can be VERY resistful creatures; especially the most assertive and energetic people who thrive in freewheeling, fast growing, entrepreneurial companies.

The Japanese learned that the application of Scientific Management works infinitely better if the people doing the work participate in creating the standards and making the continual improvements. That is, the drive to continually improve can not be imposed from the outside or from above, it must come from the team themselves.

Everything a business does needs to be thought of as a process; even the most creative of things.

All processes need to be standardized, so that they can be managed and improved.

Things should be made as simple as possible; but no simpler. This means sometimes it’s complicated, so it’s hard.

Any collection of “Best Practices” should be like the U.S. Constitution; a collection of the minimum amount of law (standardization) required to maintain order.

There are always “Milestones” along the way, or bases that must be tagged, in order to score. That is, quality checks should happen often, and at the very minimum, every time the work moves downstream to another person, and always before being delivered to the client.

The Role of Trust and Respect

The role of trust and respect for people can not be overstated. In Japan, when this system was refined, lifetime employment was the rule. And still to this day, the difference between the pay of management and the workers is not the astronomical differences we see in the west, particularly in the United States. This allows for genuine trust to be developed between all individuals in the company. So if a 10-person work team figures out how to do the same amount of work, in the same amount of time, with only five people (this happens often), they have no fear that the five people will loose their jobs. Those five people trust that they will be moved to another area of the business that needs additional work, to improve the output of the entire company.

Japanese culture is such that they have immense respect, and engage in respectful acts for people that follow them, including those they don’t even know. It’s not just about bowing and taking off your shoes indoors. For anyone who has visited Japan, this respect is obvious once one has visited their public restrooms. Long before I visited Japan I had observed (out loud) that the cleaner the public restrooms in an area are, the more civilized that area generally seems to be; in airports, for example. By that measure, all of Japan is at the peak of civilization. Japanese people would never dishonor the next user of a public restroom by leaving it worse than they found it. It’s in this culture that treating the next person who receives your work, in any work process, as “the customer.” The workers do not chafe against quality checking their own work so that “the customer,” the next person in the process who receives their work, receives that work virtually defect free. It’s engrained in their culture.

I don’t know how we do it, but we need to further develop this culture of trust and respect.

Quality Improvement Tools

These tools go by MANY names: Most business executives today know what we are talking about when we call them “Lean Six Sigma." They used to be called Industrial Engineering or Scientific Management (this is my preferred term). Then Quality Management. Then Total Quality Management. Other names have included Continual Improvement; Statistical Process Control; Statistical Quality Control; the Toyota Production System (TPS); or even just Kaizen. Someday they will be called something else.

Kaizen Project (or Kaizen Event): Discussed above.

DMAIC: Define Measure Analyze Improve Control. This is Six Sigma's primary tool that should be applied in all but the simplest Kaizen Projects. This is where the “science” in Scientific Management begins. If we don’t measure performance at the beginning then we can’t prove how much progress we have made.

Standard Work (Documentation): Discussed above.

Process Mapping (or Flowcharting): A process map or flowchart is a graphical representation of a business process.

Stabilized Process: Discussed above.

5S System is designed to improve efficiency through a systematic approach to organization and cleanliness in the workplace. The system includes five fundamental guidelines (five S’s) that help improve workplace efficiency. The five S’s are Sort, Set, Shine, Standardize, and Sustain.

Andon: All quality systems need a mechanism to “stop the presses” when non-conforming (“defective”) work is about to flow downstream. An “Andon Cord” was a wire in Japanese factories that line workers could pull if they found a defect that they could not fix before the product was pulled into the next process. Modern quality systems have many different means to ensure non-conforming work does not flow downstream. Andon is a key feature because not allowing non-conforming work to flow downstream needs to be firmly established in a culture, for a quality system to operate.

Kanban: An incredibly simple, and even more powerful scheduling system for all nature of physical and knowledge work.

MORE TOOLS

Scientific Method: Observe Hypothesize Predict Test Repeat.

Bottleneck Analysis Structured way of looking at workflows.

Just-in-Time (JIT) On-demand system of production.

Value Stream Mapping Analyzing and optimizing a process.

Root Cause Analysis (RCA) Method to get the foundation of an issue.

Error Proofing Analysis tool based on prevention.

Our Processes

As everyone who has been to a Pete Fowler Construction office knows, we have Process Posters that hang on the wall. These are a summary of our top-level processes. Right now, they are our “Sheet Music.” These are the “charts” we are jamming to. Tremendous variation in how the music gets produced and performed is a good thing. As long as it’s high quality!

The contents of our current Process Poster were not carved in stone, and carried down from a sacred mountain top. Our processes will be continually improving, forever. The way it’s laid out was performed mostly by Pete Fowler. This is natural for a small business. But we are bigger now and it’s time for us to move past Pete’s ideas, because as Kenneth Blanchard said: “None of us is as smart as all of us.” Remember: our magical information system was mostly Pete’s ideas in the beginning. But we opened it up to all of our ideas with the “Feature Requests/Bug Reports” tool and it blossomed into the magical tool set it is today.

At this point, our company processes are a completely engineered system that works. Removing or changing aspects of the system may require top-level system knowledge and understanding, so you might have to bring Pete into the process, in the beginning, to make sure important components that are created “upstream” continue to work with the components that are not made until later, “downstream.” As long as the elimination or replacement does not violate that which is not negotiable.

What Is Not Negotiable?

Pete Fowler Construction’s Values

Everyone who has worked at Pete Fowler Construction has heard about our values, directly from Pete Fowler; usually in the first week of employment. We are not kidding. OUR CORE VALUES ARE NOT NEGOTIABLE.

We elaborate “What Our Values Mean In Practice” on our public website. This 2-level Work Breakdown Structure should, literally, be used as a quality control checklist.

What Else Is Not Negotiable?

Our Brand: We make people think and (more importantly) feel:

“Those people are smart.” (TPAS)

“Those people have their act together.” (TPHTAT)

“My project is safe in their hands.” (MPISITH)

If we think the work is awesome, and the clients think and feel TPAS, TPHTAT, and MPISITH, then its high quality!

Consistency: Because consistency breeds comfort. So we all have to buy into, and use the Standard Work / Best Practices, that the people doing the work create and teach us, even if we would prefer to do it our own way.

What Is Negotiable?

Virtually everything else.

Other Pete Fowler Construction Resources on Quality

Organizational Maturity by Pete Fowler 5/14/2019

The "Definition of Quality" by Pete Fowler 6/19/2019

Construction Quality Management Resources by Pete Fowler 7/9/2019

Quality Control for Construction Maintenance, Repairs & Improvements 10/23/2014 64 page seminar presentation materials.

Managing Construction Quality 2008 by Peter D. Fowler

CASE STUDY Construction & Quality Management: A Homeowners Association in Trouble. Another edition in our "How To Save Your Community A Million Bucks" series

CASE STUDY Construction & Quality Management: Prioritizing Maintenance & Repairs: How to Save Your Community a Million Bucks

Building Insurance, Inspections & Quality: Closing the Loop 6/23/2016